- Local: (516) 346-4636

- Toll-Free: (800) 886-6060

- Fax: (516) 346-4366

- Email: kflynn@nationalwebbing.com

When you're deciding on webbing for your project, choosing the wrong material can lead to frustration, safety concerns, and unnecessary costs. Perhaps you're concerned about durability or whether your webbing can withstand exposure to water and sunlight. Or maybe you've previously chosen webbing that faded quickly or weakened unexpectedly. Understanding the fundamental differences between polypropylene and nylon webbing can save you time and prevent these headaches.

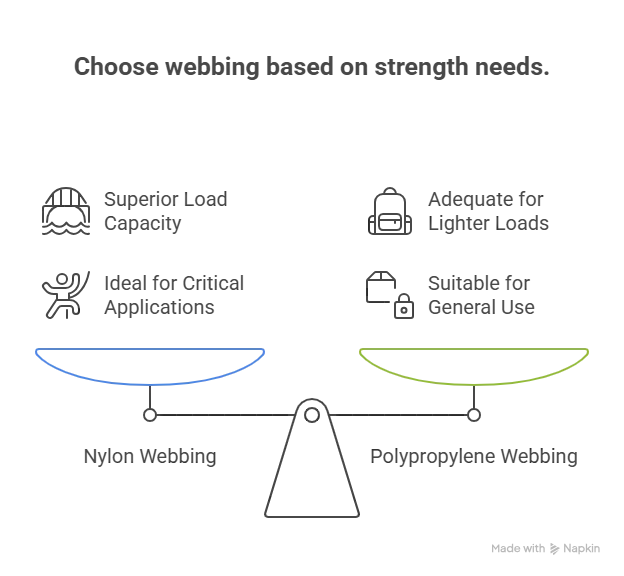

Choosing the correct material between polypropylene and nylon webbing is crucial because each has specific strengths that suit distinct applications. For applications demanding extreme strength and durability, nylon webbing is the superior choice. Conversely, polypropylene offers clear advantages for lighter tasks and environments exposed to water.

When strength matters most, nylon webbing is the superior choice. Nylon consistently outperforms polypropylene in load-bearing scenarios. It withstands greater tension and heavier loads, making it a safer and more reliable option for applications like harnesses, climbing gear, and heavy-duty cargo straps. For instance, nylon webbing typically holds up to three times the weight that polypropylene can manage without compromising integrity.

Polypropylene, although less robust than nylon, is still strong enough for general, non-critical uses. It performs well for securing lighter loads and tasks where extreme strength isn't essential, such as backpack straps, furniture webbing, and general tie-downs.

Choosing nylon webbing is the right call when absolute strength and safety are paramount, while polypropylene is suitable for lighter, everyday applications.

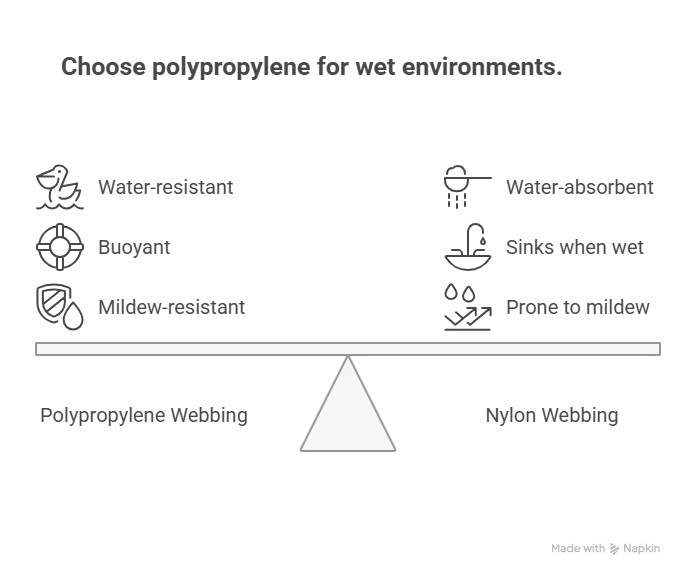

When your project is exposed to consistent water, such as in marine environments or outdoor use, polypropylene webbing offers significant advantages. Polypropylene is inherently water-resistant, meaning it doesn't absorb water and remains buoyant. This property makes it ideal for boating, dock lines, and any application involving prolonged moisture exposure. Additionally, polypropylene resists mildew and decay better than nylon when exposed to wet conditions.

In contrast, nylon webbing absorbs water, causing it to stretch and weaken slightly when wet. This characteristic makes nylon less suitable for prolonged exposure to water, which can potentially affect performance and safety in marine settings. While nylon dries eventually, the temporary weakening can compromise load stability.

Therefore, polypropylene webbing is the wise choice in wet environments, mainly in marine applications, where staying dry and buoyant is crucial.

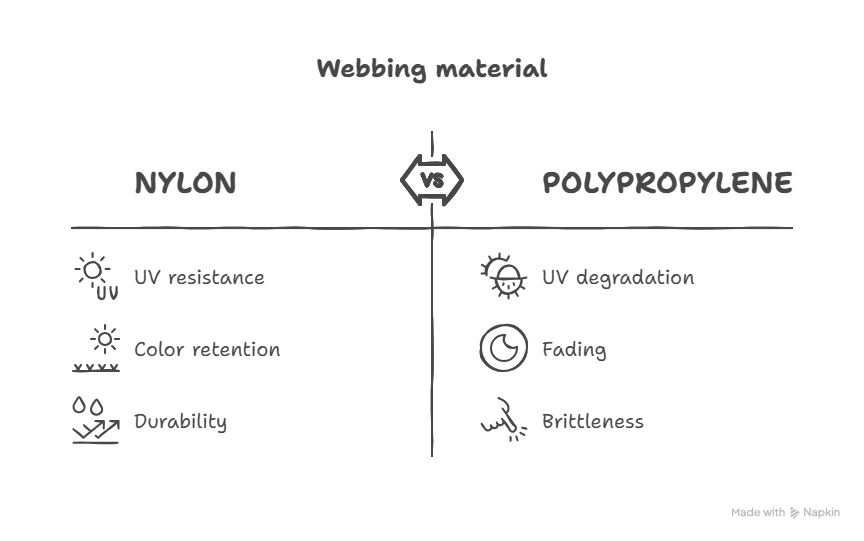

Exposure to sunlight can significantly affect the durability and appearance of your webbing material. Polypropylene excels in UV resistance, retaining its vibrant color even in prolonged periods of direct sunlight. It doesn't fade quickly, making it ideal for outdoor furniture, poolside gear, and other long-term outdoor applications.

On the other hand, nylon webbing is more vulnerable to UV degradation. Over time, exposure to sunlight causes nylon to fade and become brittle, reducing its strength and effectiveness. Frequent replacement becomes necessary, resulting in increased long-term costs.

If your project involves prolonged outdoor use and you want the webbing to maintain its appearance and durability, polypropylene offers a distinct advantage over nylon.

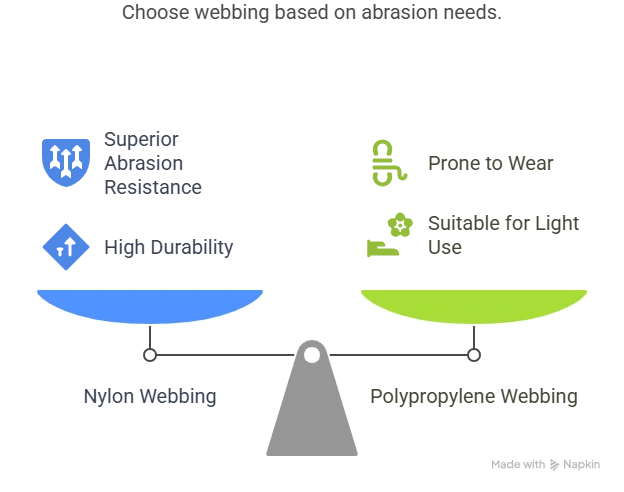

In scenarios involving constant friction or rough usage, nylon webbing is distinctly superior. Nylon's abrasion resistance ensures it withstands continuous rubbing, friction, and heavy use without fraying or breaking down easily. This makes nylon particularly beneficial for safety harnesses, tow straps, and heavy-duty cargo handling, where durability directly impacts safety and reliability.

Polypropylene, though strong in other ways, is more prone to wear under abrasion. It frays quicker than nylon when repeatedly rubbed or scraped against rough surfaces. Thus, polypropylene is best suited for applications where abrasion resistance is less critical, such as securing lightweight cargo, backpack straps, or supporting light furniture.

For long-term, high-friction environments, nylon webbing is undeniably the more durable option.

Stretching behavior varies significantly between polypropylene and nylon webbing, influencing their respective ideal applications. Nylon webbing offers elasticity, stretching under load, and returning to its original length once the load is removed. This elasticity helps absorb shocks and sudden forces, making nylon an excellent choice for climbing harnesses, seatbelts, and safety straps.

Polypropylene webbing has minimal stretch, remaining relatively stable under tension. This property makes polypropylene ideal for situations where length stability is essential, such as in securing cargo or outdoor furniture, where sagging could be problematic.

When selecting webbing, consider whether elasticity and shock absorption (such as nylon) or length stability (like polypropylene) best suits your needs.

Polypropylene webbing is significantly lighter than nylon, making it easier to handle, sew, and install. Its lightweight nature is beneficial in projects where overall weight is a concern, such as hiking gear, lightweight backpacks, and portable outdoor equipment.

Nylon, being denser and heavier, adds noticeable weight, particularly in larger applications. While this weight contributes to durability and strength, it can make handling and installation slightly more challenging.

If your project prioritizes lightweight construction and ease of handling, polypropylene webbing is the ideal choice.

Nylon webbing generally comes at a higher price due to its superior strength, abrasion resistance, and durability. For critical safety applications, such as climbing gear or automotive safety harnesses, the extra expense of nylon is easily justified by its superior performance and reliability.

Polypropylene webbing offers a more economical solution for less demanding uses. It is significantly cheaper, making it an ideal option for everyday tasks where extreme durability isn't necessary.

Choose nylon when performance justifies the cost, and select polypropylene when cost-efficiency aligns with your project’s requirements.

Ultimately, deciding between polypropylene and nylon webbing hinges on your specific application needs:

· Choose nylon for maximum strength, abrasion resistance, elasticity, and long-term durability, particularly in safety-critical roles.

· Select polypropylene for environments exposed to water or UV light, lighter loads, cost-effectiveness, and when weight is a critical consideration.

If you're still uncertain or have a unique application, consulting a professional can clarify your choice. Our experienced team understands the nuances of webbing materials and is ready to help you make the ideal selection for your specific needs.