- Local: (516) 346-4636

- Toll-Free: (800) 886-6060

- Fax: (516) 346-4366

- Email: kflynn@nationalwebbing.com

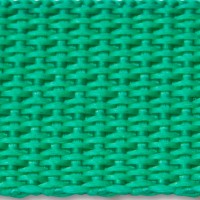

Webbing is considered a woven fabric that is constructed from in a variety of different material compositions, strengths, widths, and fibers. Webbing is commonly used to replace applications that traditionally used a rope, and it is often found in everyday life (backpack straps, seat belts, and towing). Webbing is also widely used in extreme sports like climbing and parachuting, as well as intensive military operations.

Webbing is commonly sold as either tubular or flat. Each form offers unique properties, so if you have questions, make sure to reach out to our team. We specialize in both nylon webbing and polypropylene webbing.

Flat webbing consists of solidly woven fibers that are created in a varying degree of widths and thicknesses. This manufacturing style achieves high breaking strengths that can carry out many functions and applications. Flat shaped webbing is most commonly sewn into another, larger product. Seatbelts are flat webbed materials that we trust with our lives, but they are only a small piece of the car. Flat webbing is known to be stiffer than tubular fabrics.

Tubular webbing is more flexible and thicker than flat webbing. Tubular webbing is commonly found in filters, hoses, and coverings when a tube is needed. This style of webbing is pliable and soft, which makes it great for uses that its counterpart could not do. Knowing the difference between both types is essential for acquiring webbing that bests suits your needs.

Not only is the style of webbing important, so is the materials selected. We proudly offer a wide array of materials including, organic cotton, polypropylene, and nylon. Each material boasts its strengths and flaws that are different from one another. Give us a call today to talk through your material choice options.

Related Reading: