- Local: (516) 346-4636

- Toll-Free: (800) 886-6060

- Fax: (516) 346-4366

- Email: kflynn@nationalwebbing.com

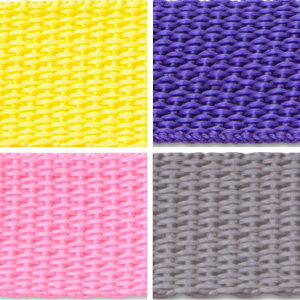

When choosing a material for your webbing needs, there are many options. Poly webbing and nylon webbing are popular materials used for slings. Polyester and nylon allow maximum control and provide a reliable and safe material.

When choosing the best material for your sling, consider the following:

· Stretch – Depending on your application’s needs, you may need a material that provides more stretch. If this is the case, go with nylon lifting slings. However, if you’re concerned with your sling stretching too much, opt for poly webbing.

· Load Capacity – When choosing your material, ensure you can avoid shock loads and do not exceed working load limits. Check OSHA’s guidelines for webbing sling-rated loads. OSHA bases its ratings on things such as type of hitch and material strength.

· Temperature – If your slings will be in extreme temperatures, consider chain or wire rope lifting equipment. Nylon and poly webbing do not work well in temperatures below minus forty degrees Fahrenheit or above 180 degrees Fahrenheit.

· Fit – The fitting must be the correct size and shape. If you are working with a multiple-leg sling, have a trained professional review the sling so you do not overload any leg.

· Chemicals – Certain chemicals, such as alkalis and acids, will affect the strength of your sling. UV light can also impact the material’s strength. Nylon webbing is resistant to many chemicals but will react poorly to bleaching agents and acids. If your sling will come into contact with these substances, choose poly webbing instead.